Wall Mounted Industrial And Mining Lamp

Wall - mounted industrial and mining lamps are essential lighting fixtures designed specifically for installation on walls in industrial and mining environments. They play a crucial role in providing reliable and efficient illumination to enhance visibility and safety in these often harsh and challenging workspaces.

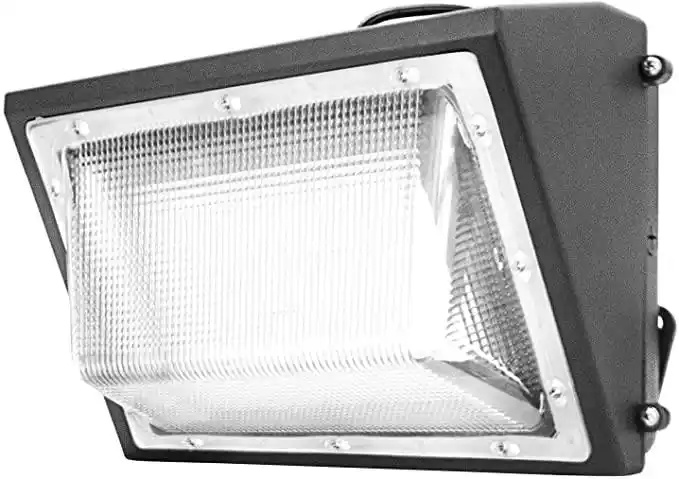

The housing of a wall - mounted industrial and mining lamp is typically constructed from robust and durable materials. Cast aluminum is a common choice due to its excellent strength, lightweight nature, and good heat - dissipation properties. Stainless steel is also utilized in some cases, especially when there is a need to withstand high levels of corrosion from chemicals or moisture present in the environment.

The housing is designed with a focus on protection. It has a sealed structure to prevent the ingress of dust, water, and other contaminants that are prevalent in industrial and mining settings. High - quality gaskets made of materials like silicone or rubber are used around the edges and openings to ensure a tight seal. This not only safeguards the internal components but also helps in maintaining the integrity of the lamp in explosive or hazardous atmospheres, if it has explosion - proof features.

Additionally, the housing is usually designed to be impact - resistant to withstand accidental collisions with tools, equipment, or other objects in busy work areas.

The light source employed in these lamps can vary, but LED (Light - Emitting Diode) technology is increasingly popular. LEDs offer several advantages such as energy - efficiency, long lifespan, and low heat generation. The LED module consists of multiple high - power LEDs that are carefully mounted on a circuit board. The arrangement and number of LEDs determine the overall light output and the distribution pattern.

To optimize the light output, the lamp incorporates optical components. The lens is often made of toughened glass or a high - grade, impact - resistant plastic. It serves two main purposes: to protect the light source from external impacts and to shape and direct the light. Some lenses are designed to provide a wide - angle illumination for covering a large area on the wall side, while others may have a more focused design for directing light to specific work areas or objects at a distance. There may also be a reflector inside the housing, usually made of a reflective material like aluminum, which helps to direct and concentrate the light rays from the source to enhance the illumination efficiency.

A key feature of the wall - mounted industrial and mining lamp is its mounting bracket. This is designed to securely attach the lamp to the wall. The bracket is typically made of the same durable materials as the housing, such as steel or aluminum alloy, to ensure it can support the weight of the lamp and withstand the vibrations and forces experienced in industrial and mining operations.

It is engineered with precision to provide a stable and reliable connection. There are usually multiple holes or slots on the bracket for fixing it to the wall using screws, bolts, or other appropriate fasteners. Some mounting brackets also offer adjustability in terms of the angle at which the lamp is mounted. This allows for fine - tuning the direction of the light to achieve the best illumination for the specific area or task at hand.

Inside the housing, the electrical components are carefully selected and designed for safety and proper functioning. In the case of LED lamps, there is a driver circuit that converts the input AC voltage from the power supply into the appropriate DC voltage and current required by the LEDs. The driver is usually enclosed in a separate compartment or protected area within the housing to prevent electrical arcing or sparking that could potentially ignite explosive substances in hazardous environments.

The wiring is insulated with high - quality materials and routed in a way that minimizes the risk of wire abrasion or short - circuits. Connectors and terminals are designed to be secure and reliable, ensuring a stable electrical connection. For lamps with other light sources like high - pressure sodium lamps or metal halide lamps, additional components such as ballasts are included to regulate the voltage and current for proper lamp operation.

When the wall - mounted industrial and mining lamp is connected to a power source, the electrical current flows through the relevant electrical components. For LED - based lamps, the AC voltage is first processed by the driver circuit, which converts it into the suitable DC voltage and current for the LEDs.

Once the LEDs receive the appropriate electrical energy, they emit light through the process of electroluminescence. The light rays then pass through the lens and are directed by the reflector (if present) to illuminate the desired area on the ground, work surface, or other target areas adjacent to the wall where the lamp is mounted. The design of the optical components ensures that the light is distributed effectively to meet the specific lighting requirements of the industrial or mining environment.

As they are mounted on walls, these lamps do not take up valuable floor or work area space. They can be installed at strategic locations along the walls of industrial buildings, tunnels, or workspaces to provide illumination exactly where it is needed. The installation process is relatively straightforward, usually involving fixing the mounting bracket to the wall and then attaching the lamp, making it a convenient choice for lighting up specific areas.

Once properly mounted, wall - mounted industrial and mining lamps offer a stable source of illumination. They are not easily moved or displaced, providing consistent lighting for tasks that require a fixed light source. This is particularly useful for work areas where workers need reliable and unchanging light conditions for activities like machinery operation, assembly work, or inspections.

Thanks to the adjustable mounting brackets in many models, the direction of the light can be customized to suit different needs. Workers can direct the light towards specific workstations, equipment, or areas that need to be brightly lit, maximizing the effectiveness of the illumination and enhancing safety and productivity.

In factories, manufacturing plants, and warehouses, wall - mounted industrial and mining lamps are used to illuminate work areas, assembly lines, storage racks, and aisles. They can be installed at regular intervals along the walls to provide even and sufficient lighting throughout the facility. In areas where there are hazardous substances or explosive atmospheres, explosion - proof wall - mounted lamps ensure safe illumination.

In underground and surface mining sites, these lamps are mounted on the walls of tunnels, shafts, and work areas. They provide illumination for miners to carry out tasks such as drilling, hauling, and equipment maintenance. The durable construction and ability to withstand the harsh mining environment make them an ideal choice for lighting in these areas.

In areas dedicated to equipment maintenance and inspection, wall - mounted lamps are often used to provide focused lighting on the machinery or components being worked on. The adjustable angle of the lamps allows for precise illumination, helping technicians to identify any potential issues or perform necessary repairs more effectively.