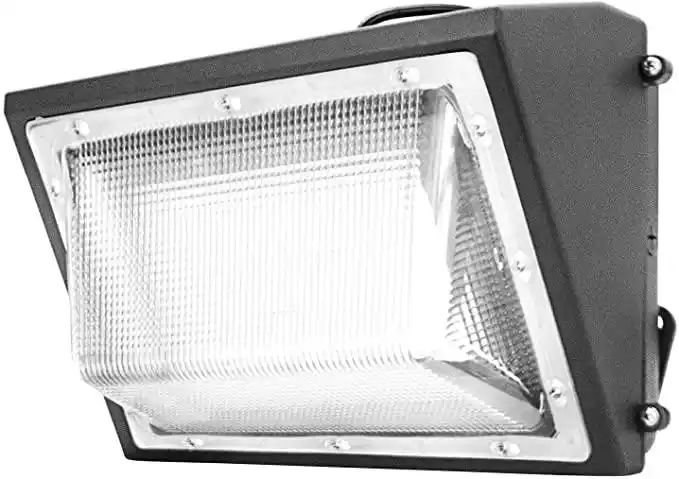

Wall Mounted Factory Light

Wall - mounted factory lights play a crucial role in industrial lighting. They are designed to provide efficient and reliable illumination in factory environments, ensuring that workspaces are well - lit for the safety and productivity of workers.

Wall - mounted factory lights play a crucial role in industrial lighting. They are designed to provide efficient and reliable illumination in factory environments, ensuring that workspaces are well - lit for the safety and productivity of workers.

The housing of a wall - mounted factory light is typically made of durable materials such as aluminum alloy or steel. These materials offer excellent resistance to corrosion, which is essential in factory settings where there may be exposure to chemicals, moisture, and other corrosive agents. The housing is designed to protect the internal components of the light from physical damage, dust, and other contaminants. It also helps in dissipating heat generated by the light source. Some housings are equipped with fins or other heat - dissipation structures to enhance the cooling effect.

Traditional Light Sources: In older models or in some applications where cost - effectiveness is a priority, high - intensity discharge (HID) lamps like high - pressure sodium (HPS) or metal - halide (MH) lamps are used. High - pressure sodium lamps emit a warm - colored, yellow - orange light. They have a relatively long lifespan and high luminous efficacy. Metal - halide lamps, on the other hand, produce a whiter light with better color - rendering properties. However, both types of HID lamps have a warm - up time and may require a ballast for proper operation.

LED Light Sources: Modern wall - mounted factory lights increasingly use light - emitting diode (LED) technology. LEDs offer numerous advantages. They are highly energy - efficient, consuming significantly less power than HID lamps to produce the same amount of light. The color temperature of LED lights can be adjusted according to the specific needs of the factory environment. For example, a cooler - white light (around 5000 - 6000K) can be used for areas where high - visibility and accurate color perception are required, such as in quality - control inspection areas. LEDs also have a long lifespan, often rated at 30,000 - 50,000 hours or more, reducing the frequency of lamp replacement.

The reflector is a critical component that determines the direction and distribution of light. It is usually made of polished aluminum or other highly reflective materials. The shape of the reflector can vary, with parabolic or elliptical shapes being common. A parabolic reflector can focus the light into a more parallel beam, which is useful for long - distance illumination or for creating a spotlight effect. The lens, if present, is used to further control the light beam. It can help in diffusing the light to create a more even illumination pattern or in focusing the light for specific applications.

The mounting bracket is designed to securely attach the factory light to the wall. It is typically made of heavy - duty metal and is bolted or screwed to the wall. The bracket provides stability and allows for some adjustment of the light's angle. Some advanced mounting brackets have a swivel or tilting mechanism that enables workers to direct the light precisely where it's needed. This flexibility is important in factory settings where the lighting requirements may change depending on the layout of the work area or the nature of the tasks being performed.

When the power is supplied to a high - pressure sodium or metal - halide lamp, the electrical current passes through an arc tube that contains the light - emitting substances (sodium vapor and mercury for HPS lamps, or metal - halide salts and mercury for MH lamps). The current ionizes the gas and vapor inside the arc tube, creating an electric arc. The heat generated by the arc causes the substances to vaporize and emit light as the excited atoms return to their ground state. The emitted light is then directed and shaped by the reflector and lens (if any) to illuminate the desired area.

LEDs emit light through a process called electroluminescence. When a current passes through the semiconductor material of the LED, electrons recombine with holes, and energy is released in the form of photons. The light output of the LEDs is then directed by the reflector and any associated optics to provide the desired illumination. The power supply to the LEDs is carefully controlled to ensure a consistent and efficient light output. The use of a constant - current power supply is common to maintain the proper brightness and color temperature of the LEDs.

Wall - mounted factory lights are an excellent space - saving option. By attaching to the wall, they do not occupy valuable floor space. This is particularly beneficial in factories where floor space is used for machinery, workbenches, storage, and the movement of personnel and equipment. The lights can be installed at an appropriate height and angle to cover the work area without interfering with the workflow.

The ability to adjust the angle of the light using the mounting bracket and the directional control provided by the reflector and lens allows for targeted illumination. Workers can direct the light precisely onto the work area, such as a conveyor belt, a machining center, or a workbench. This targeted lighting helps to reduce glare and shadows, improving the visibility of the work and enhancing the overall work environment.

Thanks to their robust construction, wall - mounted factory lights are designed to withstand the harsh conditions of factory environments. The durable housing protects the light source from dust, chemicals, and physical impacts. The long - life light sources, especially LEDs, reduce the frequency of maintenance and replacement. This durability and longevity result in lower maintenance costs and less disruption to factory operations.

LED - based wall - mounted factory lights are highly energy - efficient. They can significantly reduce electricity consumption compared to traditional HID lamps. This energy - efficiency not only leads to cost - savings on energy bills but also contributes to a more sustainable operation. Additionally, the longer lifespan of LEDs means fewer replacements, further reducing the overall cost of lighting over time.

In manufacturing and production areas, wall - mounted factory lights are used to illuminate assembly lines, workstations, and machinery. They provide the necessary light for workers to perform tasks such as assembling products, operating machines, and conducting quality - control inspections. The bright and focused illumination helps to increase productivity and reduce errors.

In warehouses and storage facilities, these lights are used to illuminate aisles, storage racks, and loading - unloading areas. The clear and even illumination helps workers to locate and access products, operate forklifts and other material - handling equipment, and maintain a safe working environment. The targeted lighting can also highlight safety hazards such as low - hanging objects or spillages.

In maintenance workshops and service bays, wall - mounted factory lights provide the light needed for repairing and servicing machinery and equipment. The adjustable angle of the lights allows technicians to focus on the specific parts of the equipment they are working on, improving the efficiency and accuracy of the maintenance work.